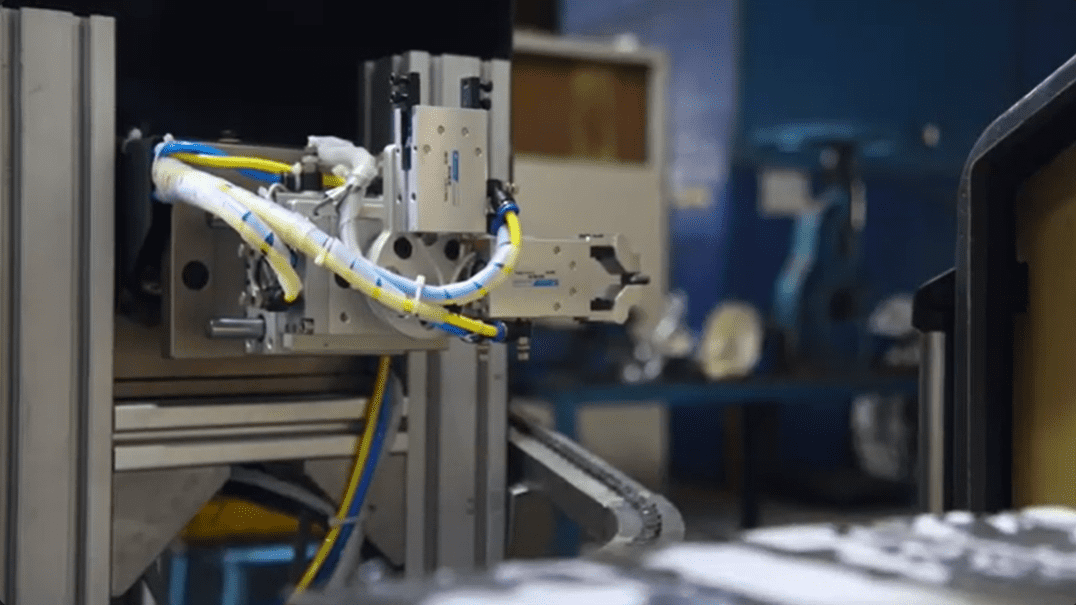

Machine Loading Arm (MLA)

The AG Machine Loading Arm is automation for CNC Machine Loading. It allows machining with very limited human intervention.

The primary feeding by multi layer chute or bowl feeder increases overall capacity and unmanned run time.

We are excited to venture into the manufacturing industry, specializing in automation systems. With our expertise and passion for innovation, we aim to revolutionize the way industries operate, providing cutting-edge solutions to enhance productivity and efficiency.

Problems faced by MSME

- Rising production costs

- Shorter delivery times

- Lack of qualified labour

- Varying Lot size

- Price pressures from competitors

Solution : Alchemy Global’ s Machine Loading Arm

- Can work 3 shifts a day without breaks

- Flexible to accommodate variants*

- Reliable

- Reduced TCO & Faster ROI

Machine Loading Arm (MLA) is an engineered Solutions for making Industries future ready.

MLA relieves your operators from monotonous job of repetitive loading and unloading. MLA offers solution to CNC Jos shops with Man power shortage. With MLA in job shop, a single operator can attend to multiple machines. The return on investment is less than 2 years.

We provide a wide range of pre-configured feeding mechanisms that is easy to use, flexible and delivering reliable performance and increased productivity at an affordable Cost.

Implementing Machine Loading Arm(MLA) for the purpose of machine tending marks the initial stride toward achieving a Lights off Manufacturing environment.

Why Machine Loading Arm

- Increased machine availability

- Increased Productivity

- Improves quality

- Consistent production output

- Single worker can tend many machines

- Reduced labour cost and quicker ROI

Control Options

- Dedicated PLC of reputed brands of choice (Delta / Mitsubishi / Omron)

- PLC logic in machine’s CNC controller (Fanuc / Mitsubishi / Siemens)

- Microcontroller

Customized Solutions

a variety of configuration options tailored to your specific CNC manufacturing requirements.

- Adjustable Chute to accommodate part variants

- Vibratory Bowl feeder for unattended machining

- Additional modules for Automated Inspection

- Automated Inspection with Auto offset correction

- Automated part cleaning / Washing

- Part transfer from one machine to another machine for second operation.

Key Features

- Robust base structure ensures maximum rigidity.

- Innovative double gripper design.

- Quick changeover for increased efficiency.

- No contact with chips and coolant, ensuring cleanliness.

- Secure gripping during both loading and unloading operations.

- Safe parking zone for the machine during machining.

- Requires less floor space, optimizing your workspace.