Machine Monitoring App (MMA)

Experience the future of CNC job shops with IoT integration. Seamlessly connect your machines, tools, and operations to enhance productivity, monitor performance, and optimize workflows.

Gain real-time insights, streamline processes, and unlock new levels of efficiency with the power of IoT technology. Transform your shop today.

We are excited to venture into the manufacturing industry, specializing in automation systems. With our expertise and passion for innovation, we aim to revolutionize the way industries operate, providing cutting-edge solutions to enhance productivity and efficiency.

Problems faced by MSME

- Lack of real-time visibility

- Inefficient Resource Management

- Maintenance Downtime and Costs

- Inaccurate Inventory Management

- Price pressures from competitors

Solution : Alchemy Global’ s Machine Monitoring App

- Real time monitoring & Data Collection

- Multi Brand CNC machine can be monitored

- Protecting assets from Breakdown

- Reduced Inventory & Maintenance Costs

AG-MMA - Machine Monitoring App is an Industrial IoT platform for Manufacturing Industries.

Industry 4.0, with its transformative technologies and digital innovations, has emerged as a game-changer for Micro, Small, and Medium Enterprises (MSMEs) around the world. MMA is an affordable on-premise Industrial IoT Platform specifically tailored for discrete manufacturing analytics, catering to the needs of MSME industries in India.

Serving as the machine data element of the Digital Factory, our innovative IIoT platform seamlessly combines IoT capabilities with efficient packaged SaaS services. By automating real-time machine data collection and transformation, MMA delivers descriptive, diagnostic, predictive, and prescriptive analytics, offering immediate and sustained value for manufacturers.

Why Machine Monitoring App

- Real-time status of shop floor

- Lower downtime by 5%-30%

- Lower maintenance cost by 10%-25%

- Increased asset availability 10%-30%

- Increased productivity by 10%-20%

- Data-driven decisions

- Improved quality

- Increased process stability

- Better traceability

- Shop-floor alerts and notifications

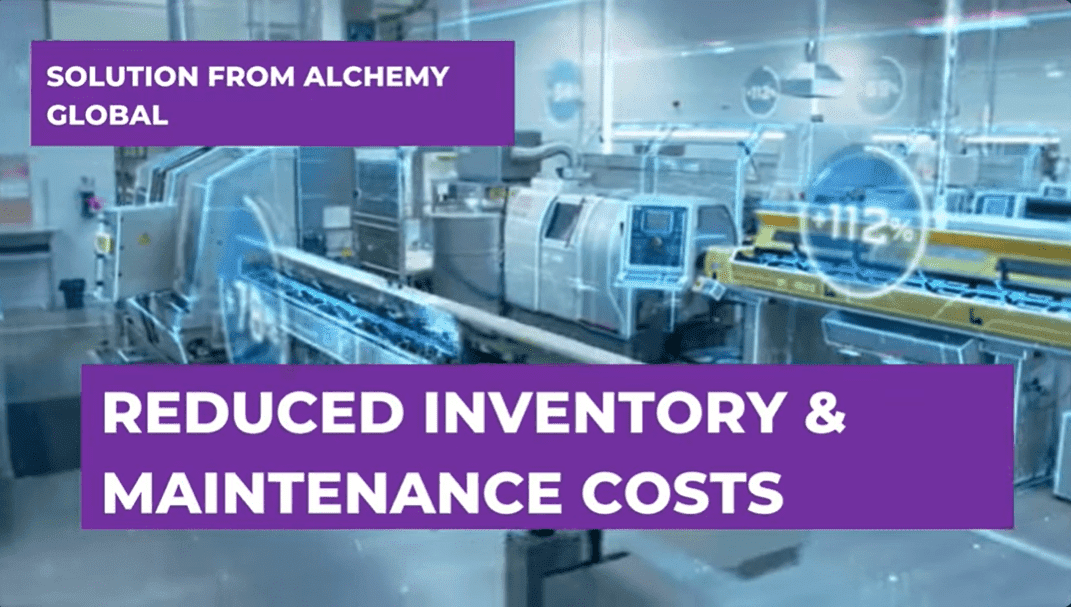

Connection Options

- Connect to any PLC supporting MT Connect, OPC UA, Modbus communication

- Custom adaptors to connect to FANUC, Siemens, Mitsubishi CNC systems.

- Microcontroller

Customized Solutions

a variety of configuration options tailored to suit your job shop’s need.

- Multi brand CNC support

- IIoT for Legacy machines with additional hardware.

- Minimum invasive IIoT implementation by Energy monitoring.

- Breakdown maintenance prediction.

- Integration with MES & ERP systems

- Optional Cloud based system

Key Features

- On Premise IIoT Solution for affordability, availability and Data Security.

- OEE Measurement and Analysis

- Smart Factory

- Choice of Simple and Advanced Dashboard Interface.

- Addon modules for scalability and Machine health monitoring.

- Supports Legacy relay operated machine.

- Capturing Operator Info and Quality Information to prepare automated Inspection reports.

- Periodic updates on Google Sheets

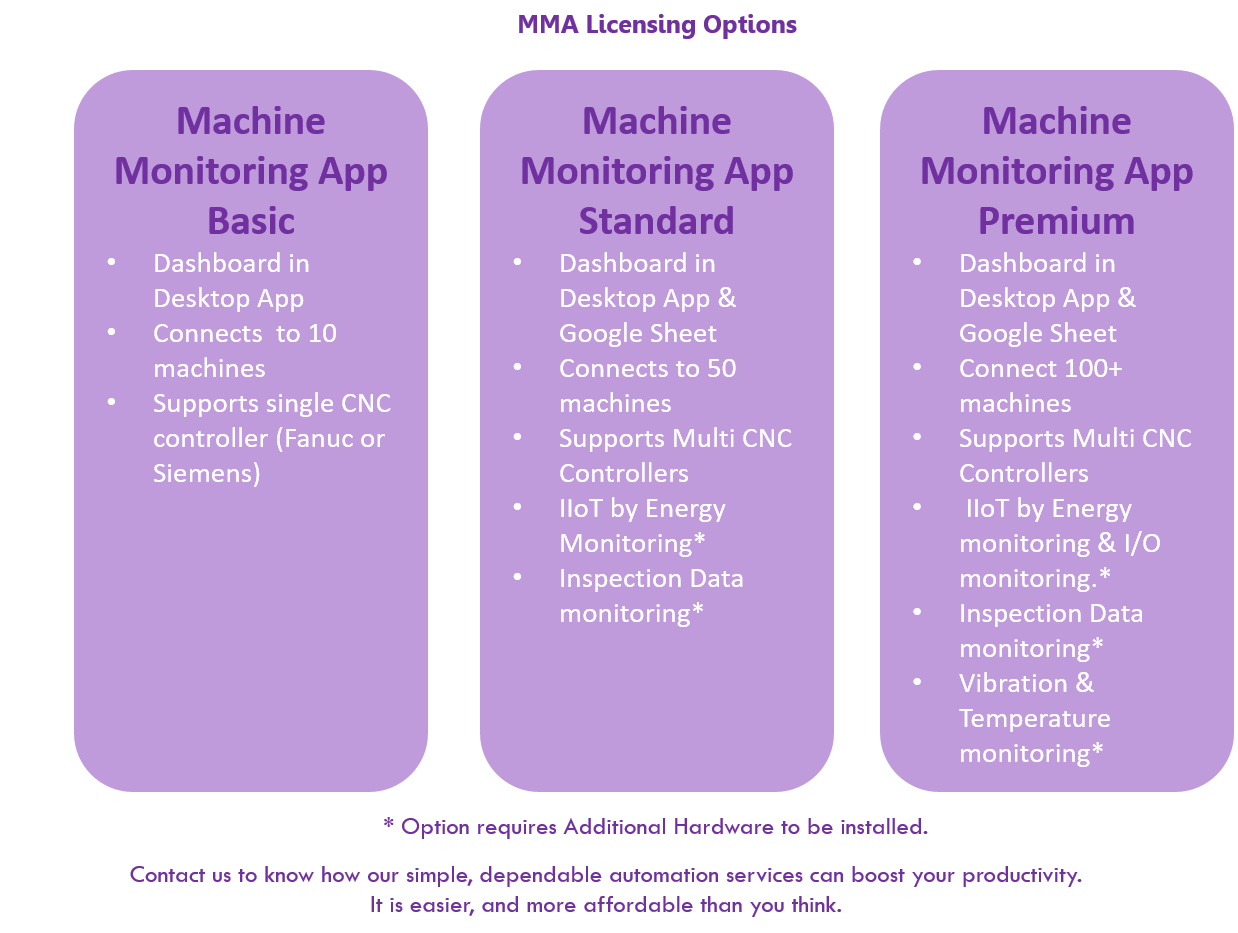

- Affordable subscription pricing model